FAQ – Production planning

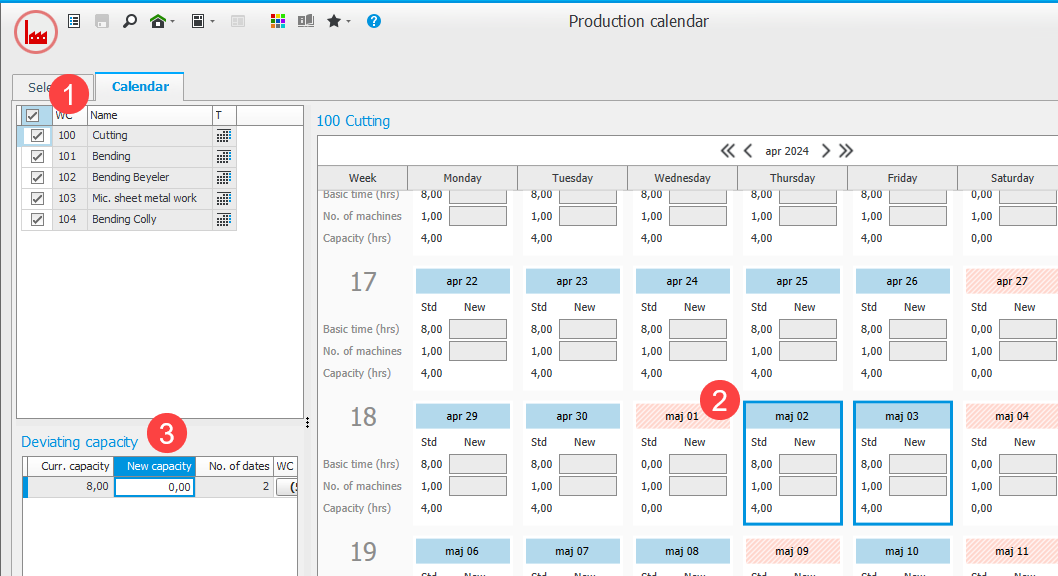

That depends on how you have set up the system, but a rule of thumb is to do it in the production calender. Mark the production groups that you would like to close, then mark the days, and finally, enter the new capacity.

The Production calender procedure.

It is preferable to use this instead of entering holidays in the Calender procedure. If you have the same Standard calender linked to everything in the system, you can also close on business days, schedule days, and delivery days.

Operations that only have time reported, the remaining time is calculated as “planned time minus reported time”. This means that the remaining time can be 0 if all planned time has been reported.

Operations that only have quantity reported, the remaining time is calculated as “planned time for remaining quantity”. I.e. if 40% of the quantity has been reported, 60% of the time remains.