Report operations

Traceability at batch level

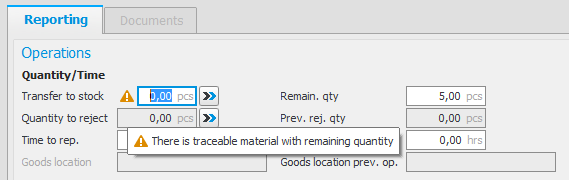

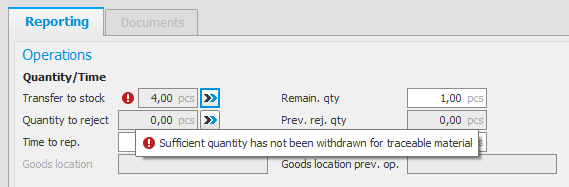

When you report an operation which has traceable material, the traceable material will in normal cases not be deducted automatically from the balance of the location. However, this can be activated via the Allow automatic withdrawal setting in the Part register. If the traceable material is not already reported, a warning will be shown when you report parts of the planned quantity on the operation. The warning is a reminder that the traceable material should be reported as soon as possible.

An operation with traceable material linked cannot be reported as finished as long as the traceable material has a remainder. An error message will then appear. This is because the traceable material must be reported in order to secure the traceability. The traceable material which is consumed must be reported so that the volume of the remaining material is zero (0) before the operation can be reported as finished.

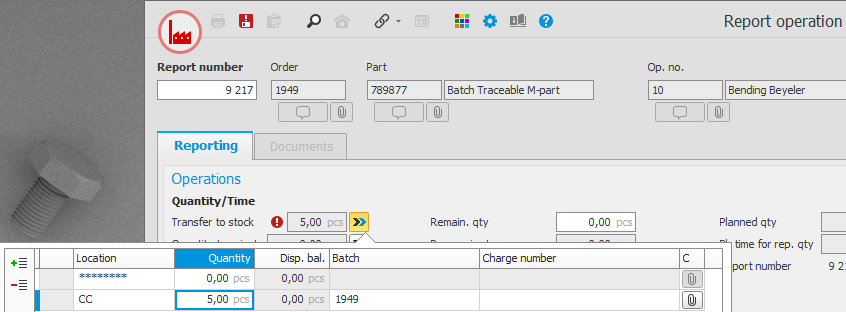

When you report the final operation with a quantity entered, a transfer to stock takes place – this is roughly the same as when arrival reporting a purchase order. By default the manufacturing order number is suggested as batch number. But you can enter any batch number you please.

You can choose the location, otherwise it will be created and named automatically according to setting. It is therefore not mandatory to open the location window during transfer to stock when you report the last operation.

Traceability at serial number level

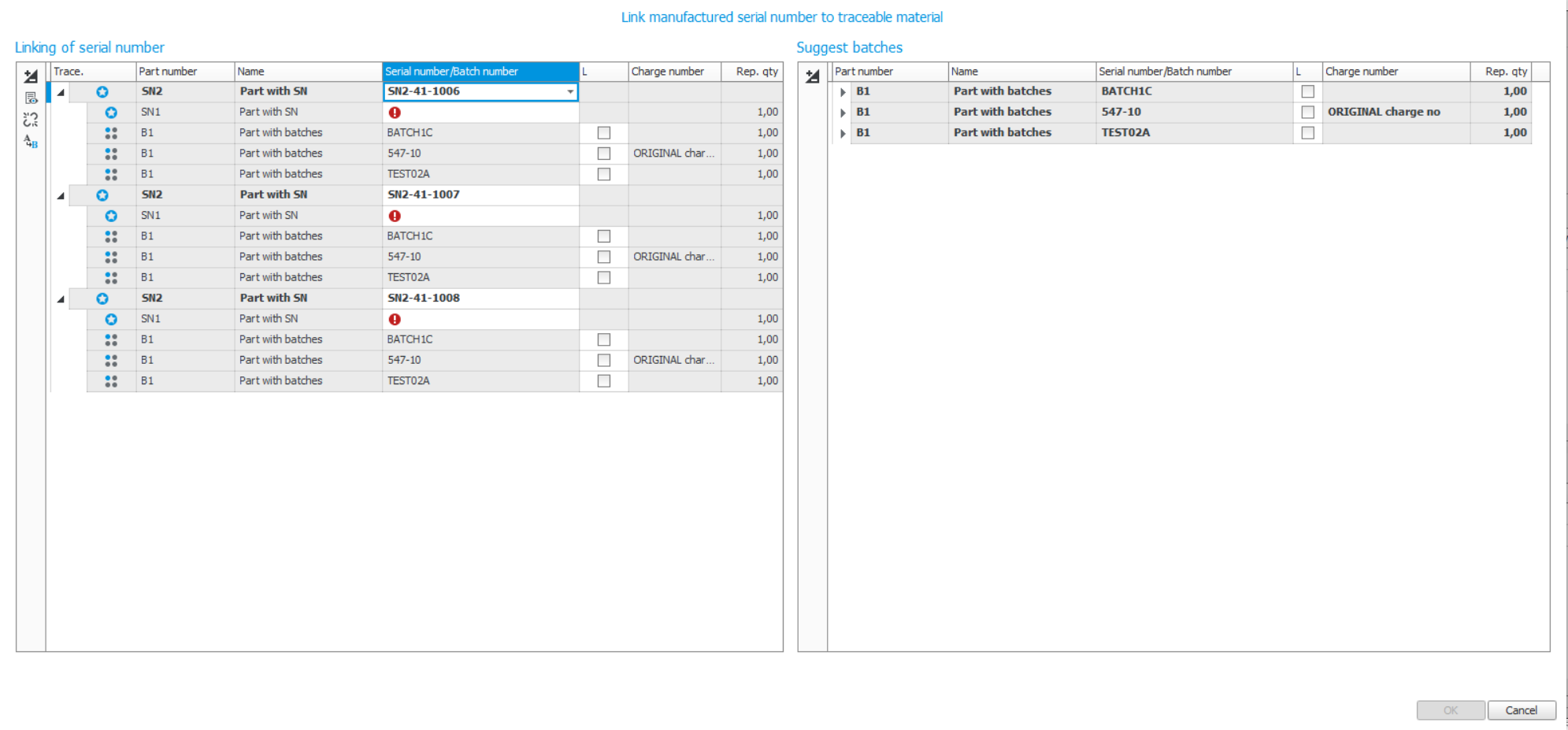

When an operation is being reported for a manufactured part with traceability at Serial number![]() A serial number is a number that is used for traceability for parts on entity level. level, and there is also traceable material linked to the operation, a dialog is shown where you link the manufactured number to traceable material. By linking serial number/batch of the material to the manufactured serial number you achieve individual traceability.

A serial number is a number that is used for traceability for parts on entity level. level, and there is also traceable material linked to the operation, a dialog is shown where you link the manufactured number to traceable material. By linking serial number/batch of the material to the manufactured serial number you achieve individual traceability.

The system setting Show dialog for serial number even though everything has already been linked determines if a dialog box should be displayed in order to link the serial number of a manufactured part to traceable material. This applies in cases where the serial number for a manufactured part is suggested, and all material has suggested batch numbers/serial numbers. This will also apply if there only is one (1) remaining serial number for a manufactured part, and one (1) in the quantity of material left to report.

If the material is traceable at Serial number (only withdrawal) level, this is where you enter the serial number for the material.

In the left-hand section of the dialog box you’ll see all serial numbers and their incorporated traceable items. Here you enter the serial number of the manufactured part that has been manufactured and the included serial numbers/batches that have been consumed, for that particular serial number. One serial number per reported quantity is reported in the dialog.

In the right hand section the opposite applies, and for material with batches you can far more quickly specify here that the same batch is used for multiple serial numbers.

The charge number is also shown in both sections. You’ll also see what volume of the serial number/batch number is withdrawn, and a warning appears if you try to link a quantity greater than the withdrawal.

When the final operation is reported and a transfer to stock takes place, you enter the manufactured serial number on the location.

If a serial number is rejected in manufacturing, the serial number cannot be used in any kind of order, and it is excluded from the stock balance.

When a serial number has been rejected in the manufacturing, the system will change the serial number's status to Scrapped.

With the  button you can hide serial numbers that are already linked, so you only see what is left to work with.

button you can hide serial numbers that are already linked, so you only see what is left to work with.

With this button  you can disconnect the serial numbers that have been linked, for example, if you want to clear them and start again.

you can disconnect the serial numbers that have been linked, for example, if you want to clear them and start again.

With this button  you can rename a serial number, if necessary, or do this later in the Serial number/Batch

you can rename a serial number, if necessary, or do this later in the Serial number/Batch![]() A batch is the set of components/products manufactured at the same time and made from the same original material. procedure.

A batch is the set of components/products manufactured at the same time and made from the same original material. procedure.