Basic data

Here we describe the different basic data you need to register in order to use the Product configurator in Monitor ERP.

You create several basic BOM and routing for the main parts (the products) in the BOM and routing procedure. A basic BOM and routing only contains the specific operations and materials which are always included in the product independent of the selected execution. Such operations might be assembly and final inspection. You then link a configuration group to the main part. Now the part becomes possible to configure.

When registering an order for such a part you must do a configuration, where you decide the execution/design/variant of the product on the order row.

Operations and material can have configured instructions. In a configured instruction you can combine static texts and images with values on variables and values from calculations in formulas you created in the configured instruction.

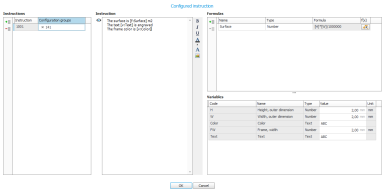

The CI button on operation and material rows opens the window Configured instruction.

In the Instructions section to the left in the window you add variants of the instruction and link each variant to one or more configuration groups. Each variant will be given a consecutive number. The first variant starts on 1001.

In the section called Variables in the bottom right corner you see the variables available in the configuration groups.

In the section called Formulas in the to right corner you can add formulas, and with the help of available variables you can calculate values and give them formula names.

In the middle section called Instruction you write the actual instruction. Both variables and formulas can be added anywhere in the instruction using the drag and drop function. An alternative is to manually enter variables and formulas in the instruction as [v:variable code] and [f:formula name]. Validations are made to make sure the entered variables and formulas are available.

In the image they are highlighted in green in the instruction, but this is only to show them clearly. Of course you can format both text, variables, and formulas, in instructions as you want.

You can at any time test the outcome of the entire instruction by using the button Preview instruction  next to the instruction.

next to the instruction.

When you are done you should save the configured instruction with the OK button.

Configuration groups are created in the procedure called Configuration groups. A configuration group contains option lists which in their turn contains the parts you should be able to select to create different variants and models of the product. In the option lists you can determine if the parts should be possible to select or mandatory to select. If custom-made products (made to measure) exist, variables are used to enter measures for different parts during the configuration. Using formulas based on variables from configuration group you can calculate and apply values for unit times and setup times, quantity, and part prices. Using rules you determine if parts should automatically be selected or excluded, based on other selected parts or results of formulas.

You create and specify option lists in the procedure called Option lists. Option lists can also be created directly in the structure in the Configuration groups procedure. An option list contains parts. The option lists can be mandatory, that is, the user has to select at least one option. Or it can be optional, this is used for example regarding additions which the user does not have to choose. It is also possible to decide how many of a certain option should be possible to select. For example if you should be able to select one or two carrier bags for a bike you are configuring.

Each part in an option list contains data corresponding to the material rows in a BOM and routing. The parts which you select during the configuration become included/incorporated parts and material in the manufacturing order that is created for the main part (the product).

By using empty fictitious parts you can also create options which will not directly affect the structure but which is used to facilitate the order registration. With rules these options can control that less options will be shown in the following sections.

You create and specify variables in the procedure called Variables. Variables can also be created directly in the structure in the Configuration groups procedure. The variables can be of the following types; numerical, string, boolean, or date. For example, a measure is a variable of the type numerical, but a variable for color is of the type called string. A variable can also contain a formula to calculate different values of the variable.

Variables can also be determined by option lists. This means they get different values depending which parts you select in the option lists. These values are either entered directly on the parts in the option lists in the configuration group or values are loaded from fields on parts in the part register. A tip is to use Extra fields on the parts for this.

In a configuration group you create a structure containing different sections, option lists and variables you have added in the configuration group. This structure works as a guide when configuring the product. Here you create the structure of the product and create the different sections needed. In the sections you add all option lists and variables you have created or added in the configuration group. In the car example you might create different sections for power train, exterior, interior, etc. You can move option lists and variables around (changing the internal order) and you can also move them between different sections. You can also move an option list into another option list, making it an underlying level.

When configuring, each section is shown as a separate page. On order documents the section functions as a grouping with a heading and a footer.

In a configuration group you can create rules which exclude parts or which automatically selects parts. A rule can exclude one or multiple options in an option list but also an entire option list or a variable. A rule can also configure that one or multiple options should be made automatically. Rules can contains complex terms which you create of options and variable values and logical and mathematical functions.

For example, you can create rules which automatically will add or exclude certain equipment based on different "packages" for the product.