Machine integration

Do you have full control over interruptions in your production? Is your production optimal? Are your post-calculations reliable? Machine integration (MI) helps you to improve your company's efficiency in production.

What is MI?

MI is a function which integrates your machines with Monitor ERP This way the worked hours, quantity, and downtime are reported automatically. You also get a good overview of the current situation and OEE follow-up.

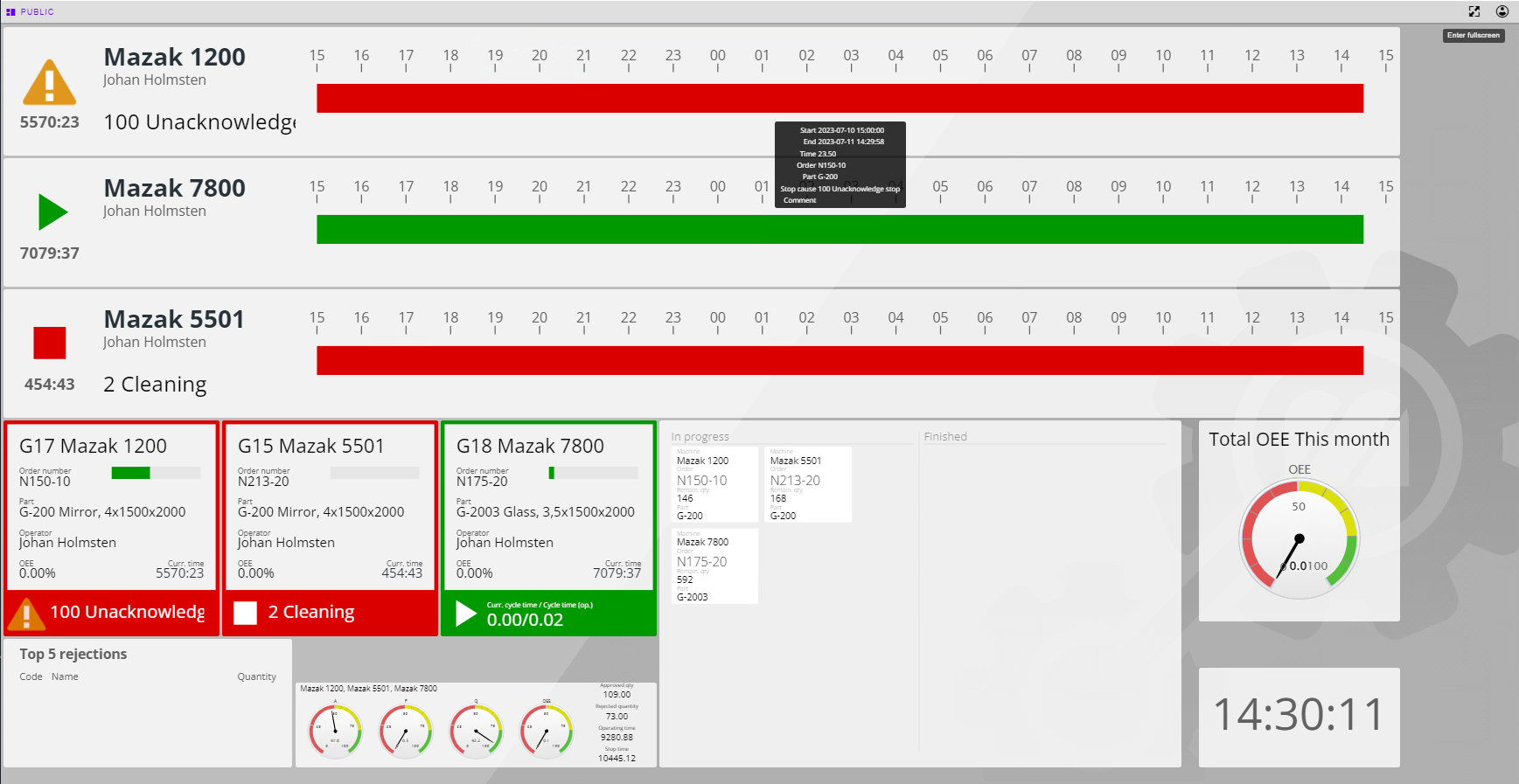

MI also has a web-based dashboard that you can configure according to your own requests. You use the dashboard to quickly get an overview of your machinery. You can display current status of the machines, view current OEE values, see which orders are being produced right now and their status, etc. When configured, you can show this dashboard on different screens in your factory.

MI Reports is a web-based report tool where you easily can create reports based on gathered data such as stops, run time, setup, rejections, manufactured quantity, OEE, on duty time, cycle time, etc., to be used as follow-up and basis for decisions.

If there is a high level of automation in your production, the follow-up of stop times and machine usage is essential.

MI provides the following support:

- Stops are reported automatically by the machine – The operator selects a stop cause and you can also follow up on on-duty time to the machine.

- Quantity is reported continuously by the machine – The manual quantity enumeration and reporting will not be needed.

- Follow-up on pace and planned finish time – It is possible to see an overview of the machinery's status. You can also use a board showing if you're on target. You will get a clear and visual machine monitoring.

What are the benefits?

There are multiple benefits of using MI:

- More accurate reporting

- Reliable post-calculations (profitable/unprofitable products)

- Less and simplified manual reporting for operators

- Improved machine monitoring

- Displaying OEE scores

- Improved control of total profitability

Underlying technology

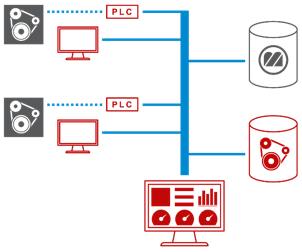

For each machine, a PLC should be linked (see illustration below), or an OPC, to interpret the signal from the machine and then report to Monitor ERP. One signal indicates that the machine is running, and another one that a piece is finished.

In addition to the PLC or OPC, you also need an MI server and one machine terminal per machine (marked red in the illustration to the left). You can then connect as many dashboards as you like (the red screen with charts).

When is PLC or OPC the best choice?

Whether you should use PLC or OPC to gather data depends on several factors. OPC enables you to gather data for more than operational status, details produced, rejections etc. With OPC you can also gather external measurements such as temperature, power consumption, grip strength, etc. These measurements can then be used to create BI solutions for e.g. finding out what the temperature was at a certain point of an order. You are also able to see exactly what the grip strength was on a particular detail produced. This does however require more from you as a customer using OPC as you are responsible for the setting-up and implementation of an OPC solution that MI can connect to. A PLC is easier to manage with the help of an electrician.

How do I get started?

Contact our sales department if you are interested in MI and they will help you get started. A pre-study by one of our consultants may be necessary to see whether MI suits your business.

This option has its own online help site, click here to be access it.