PDM Integration

Monitor ERP’s PDM Integration option automates your manual processes while also simplifying the management of BOM and part data. By automating communication between your PDM/PLM system and Monitor ERP you’ll save time and minimize the risk of errors. Forget inefficient routines and let PDM Integration optimize your workflow.

Improved product quality and increased data quality

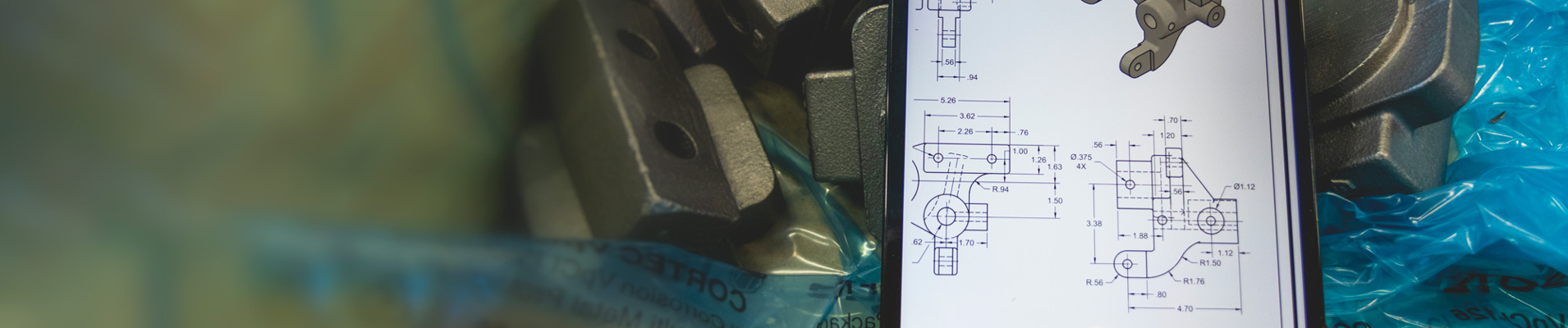

By integrating your PDM system with Monitor ERP, product and construction data, such as drawings and BOM, can be transferred over to Monitor ERP. Minimizes the risk of incorrect or outdated data being used, resulting in increased product quality and fewer delayed projects. Gives better quality BOM and routing, which increases the quality of the products and increases customer satisfaction and profitability.

Minimize duplicate work for more efficient product development

Seamless integration between PDM and Monitor ERP improves your product development process by automatically updating any design changes and updates made in PDM in Monitor ERP. Our PDM Integration eliminates duplicate work, giving you quicker product development cycles and getting products out on the market quicker.

Better stock management

Monitor’s PDM Integration gives you improved stock-keeping through up-to-date material lists, ensuring the correct parts are purchased. Improved stock management minimizes bound up capital and improves profitability.

Gives all departments access to the same, up-to-date information

The integration facilitates organizational collaboration by giving all departments access to the same, up-to-date information in Monitor ERP.

What are the benefits of PDM Integration?

- Automate the workflow between your PDM and ERP system.

- Create and update parts.

- Create and update material lists and bills of material.

- Create operations in BOM and routing.

- Create/change part revisions.

- Import and link files to part revisions and revised drawings.

- Block and set messages on parts.

- Transfer metadata to the extra fields of a part.

- Create supplier links.

What is PDM (Product Data Management)?

A PDM system contains part revisions and material lists (BOM). PDM system are often integrated with a CAD program.

PDM systems and supported formats

- SOLIDWORKS PDM Professional

- WINDCHILL via ERP connector

- CSV files

There is a standardized XML format that can be used for other systems if the original data from the PDM system can be converted to the standard format.