Loading information

In this box you enter information that is used as a basis for the loading plan for your work centers, that is, information regarding if it is of the type machine, manual work, or pool. If the group is of type subcontract, you should instead enter the information that is used as a basis for the subcontract planning and the information for the subcontract purchase.

Time precision

This field is shown if you have activated the system setting Enable hourly planning for work center. You can then via the button Change time precision  change the Day planning

change the Day planning![]() Day planning is used when you are NOT applying hourly planning. It means that all operations are planned to a date and not to a specific time on a date. to Hourly planning

Day planning is used when you are NOT applying hourly planning. It means that all operations are planned to a date and not to a specific time on a date. to Hourly planning![]() Hourly planning refers to when planning per work center is done per hour. Hourly planning is activated with a system setting. Period is then entered as date and time. You can view loading on hour basis. or Capacity via schedule (this does not apply to work centers of the Subcontract type). For hourly planning and capacity via schedule, you must enter the schedule cycle to be used as schedule. This is done under the Schedules tab. This tab becomes available when you change the time precision.

Hourly planning refers to when planning per work center is done per hour. Hourly planning is activated with a system setting. Period is then entered as date and time. You can view loading on hour basis. or Capacity via schedule (this does not apply to work centers of the Subcontract type). For hourly planning and capacity via schedule, you must enter the schedule cycle to be used as schedule. This is done under the Schedules tab. This tab becomes available when you change the time precision.

It is possible to enter different queue time. For the time precision options Capacity via schedule and Hourly planning, you can enter the queue time in number of hours (using two decimals). If Capacity via schedule or Hourly planning has been selected, and if the queue time is at least two queue days, then you can activate the setting called Round off queue time to full day. This will make the order registration using schedule or hourly planning more similar to the day planning. Without this setting you will get a shortened throughput time for orders registered using hourly planning.

For day planning, you can only enter the capacity as basic time and as an availability factor for work center. If you change from day planning and save, all the manufacturing orders where the current work center's operations have remaining quantity will be replanned. A list of all the replanned orders will then be shown.

The only thing that differs between hourly planning and capacity via schedule, is that when hourly planning is used a time is shown for hourly planning for the operations e.g. in the Priority planning and Order information procedures. The same capacity calculation is used for the two time precisions.

Number of machines

Machine. In this field you see/enter the number of machines (planning units) that exist in the work center. By default, one is displayed as the number of machines. This information is used when calculating the work center's total capacity.

Number of persons

Manual work. In this field you see/enter the number of persons (planning units) that exist in the work center. By default, one is displayed as the number of persons. This information is used when calculating the work center's total capacity.

Next to the field there is a button  which you can use to see all persons linked to the work center and thereby contribute with capacity and availability. You link persons to the work center by using the checkbox called Capacity for in the Settings for Start work section in the Personnel records – Time recording procedure. There you also enter each person's Availability in percent for the work center.

which you can use to see all persons linked to the work center and thereby contribute with capacity and availability. You link persons to the work center by using the checkbox called Capacity for in the Settings for Start work section in the Personnel records – Time recording procedure. There you also enter each person's Availability in percent for the work center.

When there is one or multiple persons linked to the work center as Capacity for via the personnel register, the field Number of persons is not possible to edit. In such cases the work center's total capacity will be calculated as: the work centers’s basic time x the person's availability. Each persons planned absence is also taken into consideration in the capacity calculation.

Number of machines per order/Number of persons per order

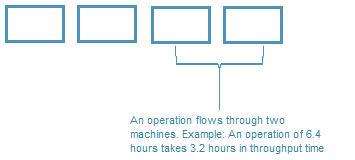

Machine and Manual work. Here you can enter how many machines or persons are used simultaneous per order. For the work center, an operation is divided in the number of machines/persons per order you have entered. The number of machines/persons affects the throughput time. For example, if the work center has two machines and you enter two machines, the throughput time is shortened with 50% compared to if one machine is used. This is the result since the two machines share the quantity to manufacture in the operation. One machine is selected by default. You can enter decimals. Please see the image below where the number of machines is set to four and the number of machines per order is set to two.

If you here enter a greater number than the number of machines or persons entered in the field above, then a warning  is shown since it is not the normal way to use this field. However, it is possible to enter a greater number of machines/persons per order than the number of machines/persons in the work center. This can, for example, be used for a work center which is not used on a daily basis or only for a few hours per day (its Basic time < 8 hours/day).

is shown since it is not the normal way to use this field. However, it is possible to enter a greater number of machines/persons per order than the number of machines/persons in the work center. This can, for example, be used for a work center which is not used on a daily basis or only for a few hours per day (its Basic time < 8 hours/day).

Availability factor

This field is multiplied by the basic time value to provide the capacity for the work center. When using day planning, you can enter any value as basic time, but when using Hourly planning or Capacity via schedule, that is not possible, and this field should be considered. The capacity based on the schedule cycle generates a gross capacity. But this value is too high to be used as a basis for loading plans. If the work center has an eight hour schedule time, the gross capacity is eight (8) hours per day. However, it does not usually mean eight hours of effective work, but a bit less than that. The availability factor reduces the gross capacity to a net capacity. This net capacity is then used as a basis for loading plans. The default value is 80 % when creating a new work center. The value must be more than 0%. The availability factor affects the same way over 24 hours.

Basic time (Basic time, pre-calculation)

Here you see/enter the basic time for the work center. If the time precision called Day planning is applied for the work center, the basic time x number of machines is used to calculate the capacity of the work center. The default basic time is eight hours per day. If the time precisions Capacity via schedule or Hourly planning is applied for the work center, the schedule will be used instead of the basic time in the calculation of the work center's capacity. In that case, the basic time is only a basis for pre-calculations for calculating throughput times and lead times in different manufacturing orders. The setting is then called Basic time, pre-calculation.

Calendar

For a work center which has Day planning as time precision, it is possible to select which calendar should apply. For work centers with Hourly planning or Capacity via schedule, you select calendar under the Shedule tab instead.

Please note! Exceptions, if any, will override capacity entered via a calendar.

Queue time

Queue times is used in lead time calculations when registering manufacturing orders. The queue time affects the "gap" between finish time for the previous operation and the start time of the work center’s operation. The queue time is always entered in whole work days when using day planning. If either capacity via schedule or hourly planning is used, then you can enter queue time in number of hours with two decimals. However, it is not whole work days or whole hours in the gap, see example below.

- Queue time

Queue time refers to time which is added to create a gap between two operations when the manufacturing order is created. It is normally stated in days, where 1 means the rest of the commenced day will be the "gap". 2 means the rest of the commenced day plus 1 full day will be the gap. For work centers with hourly planning, the queue time is instead entered in hours. The entered queue time will be added before the operation which has a value entered. 2 work days – If the previous operation finishes on Monday, then the work center’s operation will start some time on Wednesday.

Queue time refers to time which is added to create a gap between two operations when the manufacturing order is created. It is normally stated in days, where 1 means the rest of the commenced day will be the "gap". 2 means the rest of the commenced day plus 1 full day will be the gap. For work centers with hourly planning, the queue time is instead entered in hours. The entered queue time will be added before the operation which has a value entered. 2 work days – If the previous operation finishes on Monday, then the work center’s operation will start some time on Wednesday. - Queue time 2 hours – If the previous operation finishes at 9:20 AM, then the work center’s operation will start at 11:20 AM.

The lead time (L) for an operation is calculated as: L = queue time + setup time + quantity x unit time.

The queue time is the most important information for a work center under the heading Loading information. This is needed in order to be able to start using the system. If you do not enter a queue time, the lead time will probably be shorter than in reality, which means that your loading and material requirements will not be displayed in the correct/reasonable time period.

For structure orders, the queue time also affects the finish time that the included part in a structure order will get.

Round off queue time to full day

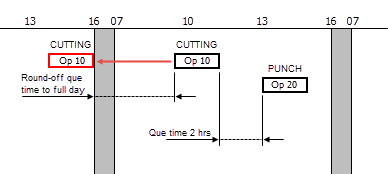

If you activate this setting the queue time will be extended so that the previous operation will be on the previous day. In the example in the image, there is two hours of queue time for the work center PUNCH in operation 20. If the setting Round off queue time to full day has been activated for the work center PUNCH, then work center CUTTING's operation 10 will be placed on the day before with a finish time at the end of the work day.

Simulation factor

The loading situation is simulated taking this factor into consideration. The default value is 100%. The loading is divided by the simulation factor. If the simulation factor is 80%, the loading will increase by 25%, that is, loading / 0.8.

Staffing factor, unit and setup

Machine and Pool. The staffing factor entered here indicates how large a share of the operating time that is staffed. Staffing factor can be entered for setup time and unit time. Man-hours are calculated as unit time x staffing factor per unit + setup time x staffing factor setup.

E.g., if two work centers are automated and served by one person, 50% will be entered for each work center. A loading of 30 hours during one week for both of the work centers will result in a requirement of 60 hours total machine time, but a requirement of 30 man-hours.

The opportunity to calculate using man-hours can be useful for several work centers in the Loading plan and Priority plan list procedures. Loading hours will then be converted into the number of man-hours needed.