Result of the CDT

By clicking the CDT![]() CDT is short for check delivery times and it is a function on order rows which calculates when the order row in question can be delivered, taking lead times and throughput times into consideration. CDT also checks if existing orders and suggestions can cover material shortages, if any, and affects when the order row can be delivered. button on quote row, customer order row, stock order – sales, and manufacturing order, you can see the result of the CDT in a separate window. A symbol on this button indicates how the order/order row is supplied according to the list below. A tooltip on the button also informs you of this in text form.

CDT is short for check delivery times and it is a function on order rows which calculates when the order row in question can be delivered, taking lead times and throughput times into consideration. CDT also checks if existing orders and suggestions can cover material shortages, if any, and affects when the order row can be delivered. button on quote row, customer order row, stock order – sales, and manufacturing order, you can see the result of the CDT in a separate window. A symbol on this button indicates how the order/order row is supplied according to the list below. A tooltip on the button also informs you of this in text form.

-

– The row is supplied by the balance.

– The row is supplied by the balance. -

– The row is supplied by existing order.

– The row is supplied by existing order. -

– Manufacturing is needed to supply the row.

– Manufacturing is needed to supply the row. -

– Purchase is required to supply the row.

– Purchase is required to supply the row.

On the button you will also see an asterisk (*) if there is an alternative work center/supplier which would result in an earlier delivery date/finish date if you should replan the order using the alternative work center/supplier.

In the result window you see the Results tab which displays the result of the delivery times check and what supplies the requirement/need (balance, existing orders, and suggestions). The tab called CDT's planning window shows how the planning will look and the Loading tab shows the loading graphically.

On the function menu in the Results tab there are different buttons to use:

-

– Expand/Minimize all rows. – This will expand/minimize the rows in the tab.

– Expand/Minimize all rows. – This will expand/minimize the rows in the tab. -

– Run the check of delivery times again. If you select/add an alternative work center/supplier you can run the CDT again using this button.

– Run the check of delivery times again. If you select/add an alternative work center/supplier you can run the CDT again using this button. -

– Go to critical operation/material. Using this button you can navigate in the table to the first operation or the first material which is critical.

– Go to critical operation/material. Using this button you can navigate in the table to the first operation or the first material which is critical. -

– Hide operations that do not include loading. By clicking this button you can also show the operations in the work centers in the order structure which do not include loading.

– Hide operations that do not include loading. By clicking this button you can also show the operations in the work centers in the order structure which do not include loading.

With the help of the result window you can investigate where there are critical operations and material, that is, which suppliers and work centers have the greatest difference between the planned delivery date/finish date and the actual delivery date/finish date. The difference is shown in number of work days. This is a help to be able to replan orders to make them ready for delivery sooner.

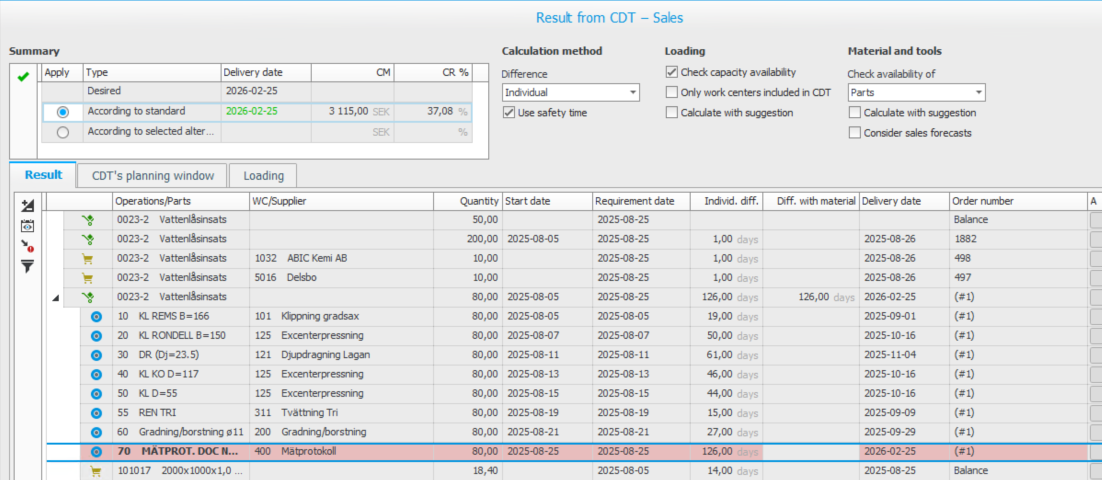

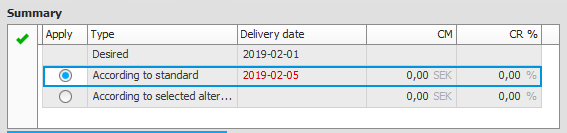

In the Summary table in the upper part of the result window you will only see information if manufacturing or purchase is required.

On the first row you see the entered delivery date/finish date of the order. On the next row you see what will be the earliest delivery date if the standard work centers are used, and also what will be the order's contribution margin and contribution ratio. On the third row you see what the order’s contribution margin and contribution ratio will be in cases when alternatives are used.

If there are alternative suppliers or work centers selected by CDT, then you can check the Apply box on the third row if you wish to use that alternative, or you can keep the default setting to use standard work centers.

By using the Confirm button  you confirm which row that should be used. The result window will then close and the delivery date/finish date will be loaded to the order.

you confirm which row that should be used. The result window will then close and the delivery date/finish date will be loaded to the order.

The Results tab displays the result of the CDT. It can be one or several of the following: balance, stock order, purchase order, purchase order suggestion, manufacturing order, or manufacturing order suggestion, that are required be able to supply the order row.

- Balance is available immediately, and therefore no delivery date is suggested for the balance row.

- Stock orders and purchase orders use the order’s delivery date.

- An existing manufacturing order uses the "New finish date" calculated by the net requirement calculation, and if that is missing, the planned date on the manufacturing order is used.

- Stock order suggestions and purchase order suggestions use the supplier’s lead time for the part. (If there is an existing order beyond the lead time, that date is suggested.)

- Manufacturing order suggestion calculates when a new order can be manufactured. Manufacturing order suggestions are expanded by default and show the critical operation and/or the material with the worst delivery date in light red.

- If there is an alternative work center or an alternative supplier for a critical row, it is displayed in the structure map.

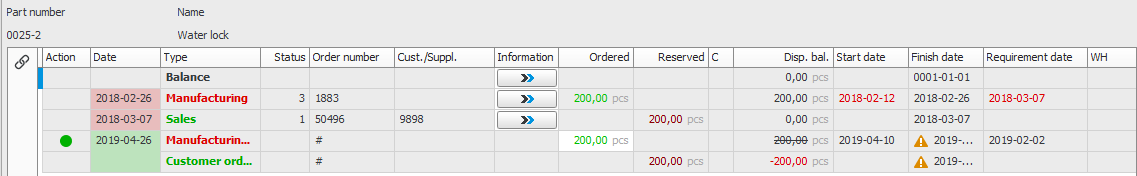

The tab called CDT’s planning window displays the planning window for the part that CDT is run for.

The planning window looks the same as in the Part register and Requirement calculation procedures. Customer orders, manufacturing orders, suggestions, and material requirements from the CDT function are marked with (CDT) in the Type column.

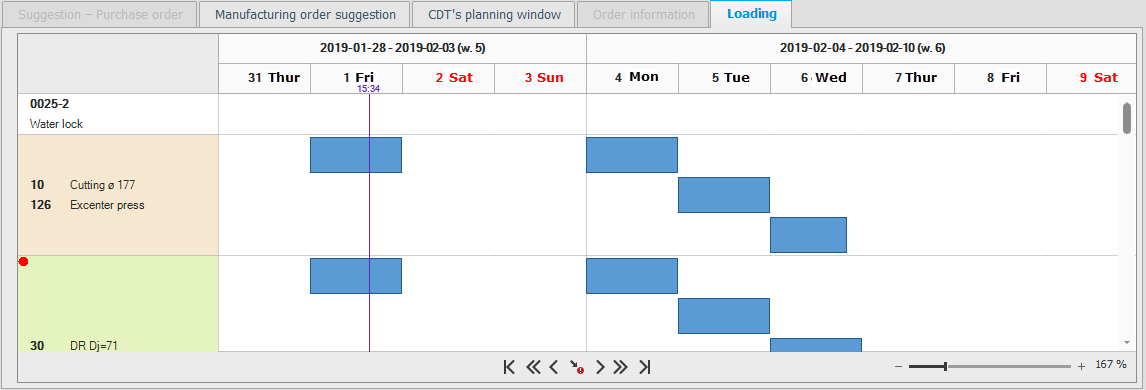

The Loading tab is active if the CDT function has created manufacturing order suggestions to supply the order/order row. Under this tab you see a loading chart for all affected work centers on the operations for the part node which contains critical operation/material. That part is shown on the first row. On the rows below you can see how the operations are positioned in relation to each other as different blocks.

Each operation's block has a color code or a pattern according to the following: blue color means existing loading for the work center, green color means the operation's loading according to the CDT, and a blue grid means loading from the CDT for another operation.

A critical operation is marked with a red dot in the left column and the block of the critical operation has a light red color. The loading chart is also positioned on the critical operation on the time axis when you open the tab.

At the bottom of the tab you can use the buttons to navigate along the time axis and also select to go directly to the critical operation. There is also a lever you can use to zoom in and out on the time axis.