New calculation model for CDT

In version 25.6 a new calculation model for CDT![]() CDT is short for check delivery times and it is a function on order rows which calculates when the order row in question can be delivered, taking lead times and throughput times into consideration. CDT also checks if existing orders and suggestions can cover material shortages, if any, and affects when the order row can be delivered. is launched. This means several important changes. If you use Check delivery times, we recommend that you go over these changes.

CDT is short for check delivery times and it is a function on order rows which calculates when the order row in question can be delivered, taking lead times and throughput times into consideration. CDT also checks if existing orders and suggestions can cover material shortages, if any, and affects when the order row can be delivered. is launched. This means several important changes. If you use Check delivery times, we recommend that you go over these changes.

Watch the video on the new calculation model.

| English |

|---|

- The main improvements in this version regard these four things:

- The calculation is always based on today's date.

- Smarter calculation of available capacity with changed logic and a new setting.

- Better management of overload to prioritize existing orders before new ones.

- Changes to the user interface to make it easier to understand the results of the calculation.

In the below sections, the changes are described in more detail.

Please note that improvements to the new calculation model will keep being developed in upcoming versions. Next up are improvements in the following areas:

- Detailed analysis of registered/ongoing stock driven orders.

- Suggestions from sales forecasts for underlying parts taken into account.

- Detailed analysis of material that is supplied from other warehouses.

The calculation is always based on today's date

The delivery time is now always calculated from today’s date instead of from an entered delivery date. Previously, the calculation could vary depending on the selected (future) delivery date (e.g., because of schedule exceptions). Now, the result will be stable and always show the fastest possible delivery time.

Smarter calculation of available capacity

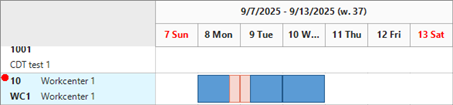

One of the most important improvements is that the system can now combine available capacity from the end of a day with the beginning of the following day. This is demonstrated in the example below.

New logic: The operation (red) fits by using the end of the Monday + the start of the Tuesday (existing loading shown in blue).

New logic.

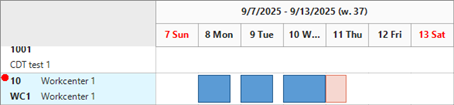

Previous logic: The same operation was placed on the Thursday.

Previous logic.

There’s also a new setting, CDT additional days, in the work center register. This setting determines if the loading can be spread out over multiple days. You can set how many additional days can be used.

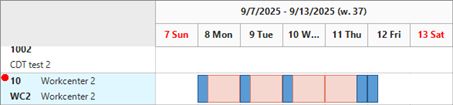

In the example below, a longer operation is shown. For the work center WC2 in the example, 2 additional days have been entered. This means the operation can be divided onto Monday and Tuesday (two days that are not consecutive to the finish date on Thursday).

New logic, with setting CDT additional days activated.

Please note that an operation being divided onto non-consecutive days will likely mean that either additional setup times or that operations for existing orders will need to be rescheduled to earlier times.

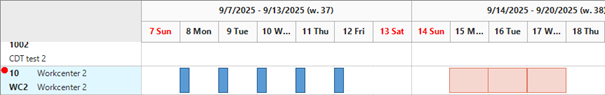

Without the setting and with the previous logic, the finish date for the operation would have been calculated to the Wednesday the following week.

Previous logic without the setting CDT additional days.

Better handling of overload

Check delivery times will always analyze the loading plan and redistribute potential overload for existing orders.

The comparison between the new and the previous logics can be summarized like this:

- New logic: Overloading will be moved back time-wise if there is capacity. If there’s no capacity, it will be moved forward. In this way, existing orders are prioritized over new orders.

- Previous logic: The overload was always moved ahead in time, which could delay already planned orders.

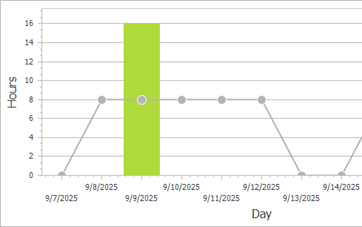

In the example below, Tuesday the 9th is overloaded. The loading is 16 hours, but the capacity is 8 hours.

Overload.

Because there is 8 hours of available capacity on Monday the 8th, Check delivery times will distribute 8 hours of loading backwards in time for these orders, and then read the Monday as fully loaded.

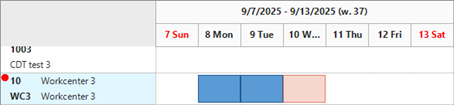

When the Check delivery times then calculates the finish date for an operation on a new order, the answer will be Wednesday the 10th because of the loading situation described above. Existing orders with overload will be prioritized over new orders. They were planned for the Tuesday but also take up the Monday.

New logic.

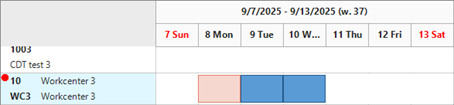

Using the previous logic, where overloading on existing orders was always moved ahead in time, the example above would have the following result: the new order would have been given a finish date of Monday the 8th, which in practice would have meant that existing orders were at risk of being delayed.

Previous logic.

Improvements to the user interface

- All results are shown in the same tab, regardless of whether the supply comes from purchases or manufacturing.

- Balance, order suggestion, and order are shown as separate rows, which makes it clear where the supply comes from and what quantity is supplied.

- When you move the cursor over a bar in the Loading tab you see capacity, loading, and order number. This helps to make comparisons between the CDT result and the loading plan.

- A separate column for diff. with material has been added. This way you can easily see if an operation is delayed because of lacking capacity or material shortage.

- This applies when date difference is calculated with the setting Individ. diff.

- The CDT settings are shown directly in the CDT dialog.

Miscellaneous

- New finish date (also applies to the Priority planning procedure) now takes number of machines per order into account.

- The setting Check included stock driven part has been removed. Instead, stock driven parts are always checked.

- The date setting for existing manufacturing order, where you could select between New finish and Planned finish has been removed. Now New finish will always be used if it has been calculated by the net requirement calculation. Otherwise, planned finish will be used.

- The tab Manufacturing order info has been removed in order to simplify the user interface. You can instead use the procedure Manufacturing order info.

- The calculation for faster alternative will no longer suggest a delivery date. Because of issues with how that date was calculated, it will now be hidden. An improved calculation model for faster alternative will be launched in an upcoming version.

- For pool planning, the average capacity for the linked work centers will now be used.