Report arrival/Receiving inspection

If Receiving inspection has been activated for the supplier, part, or order row, the following actions should be performed in the Receiving inspection procedure and not in the Report arrival procedure. If receiving inspection is activated for the order row, the entire Location box will be deactivated. You activate the receiving inspection on the order row by checking the Inspection checkbox.

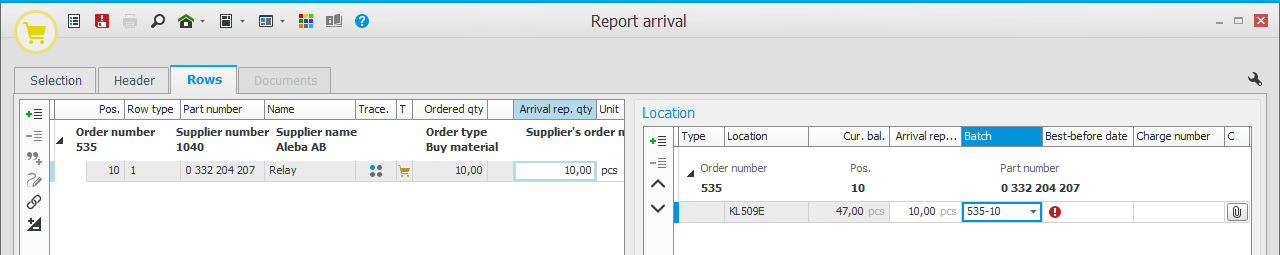

Traceability at batch level

When arrival reporting a purchased part with traceability at Batch![]() A batch is the set of components/products manufactured at the same time and made from the same original material. level, you can enter the batch number on the location in the Location box for the marked order row.

A batch is the set of components/products manufactured at the same time and made from the same original material. level, you can enter the batch number on the location in the Location box for the marked order row.

The suggested batch number for the location is "purchase order number - position number” by default, although other settings can be configured in the Number series procedure. However, you can always enter any batch number.

If the setting Apply best-before date has been activated for the part, you’ll see the Best-before date column on the location with a suggested date, or, depending on the setting on the part, it will be mandatory to enter a date. You enter best-before date per batch.

You can also enter Charge number![]() A charge number is used to provide traceability. It is the supplier's batch number, or charge number, which is linked to our batch number for a location. and link files for Certificates to the location in connection with the arrival reporting. The same batch can be added to several locations and multiple batches can also share the same location.

A charge number is used to provide traceability. It is the supplier's batch number, or charge number, which is linked to our batch number for a location. and link files for Certificates to the location in connection with the arrival reporting. The same batch can be added to several locations and multiple batches can also share the same location.

When arrival reporting a part with traceability at batch level, it is not mandatory to select a new location at which to report the batch number. If required, you can apply a system setting whereby new locations are created when arrival is reported, which are thereby named automatically and given the suggested batch number.

Traceability at serial number level

When reporting arrival of parts with traceability level Serial number![]() A serial number is a number that is used for traceability for parts on entity level., the serial number and quantity must be entered on the location. This is done under the Serial number

A serial number is a number that is used for traceability for parts on entity level., the serial number and quantity must be entered on the location. This is done under the Serial number  button in the Location box for the order row selected.

button in the Location box for the order row selected.

To quickly report multiple serial numbers in succession, one or more intervals can be reported. Enter a start number in the From column, and a Quantity, and the serial numbers will be set, with the final serial number shown in the To column.

To enter serial numbers which are not in succession, you can simply add a new row per serial number. A Prefix can be entered for all serial numbers in the interval. You can also enter Charge number and link a file for Certificate to each serial number interval in connection with the arrival reporting. Serial numbers can also be imported from a text file containing serial numbers. This is done with the Import serial numbers button  .

.

When applying traceability at serial number level the default batch number is still there (as when using traceability at batch level) and it can be changed. It is also possible to enter charge number for the location and you can link files for certificates to these.

For purchased parts which are traceable at Serial number (only withdrawal) level, you do not enter any serial numbers during the arrival reporting. They are at this stage handled in the same way as parts with not traceability.