Machine integration

Do you have control over disruptions to your production? Is your production optimal? Are your post-calculations reliable? Machine integration (MI) helps your company become even better and more efficient.

What is MI?

MI is a function that integrates your machines with Monitor ERP Monitor ERPfor automatic reporting of e.g., worked hours, quantity, and downtime. You also get a good overview of current status and OEE follow-up.

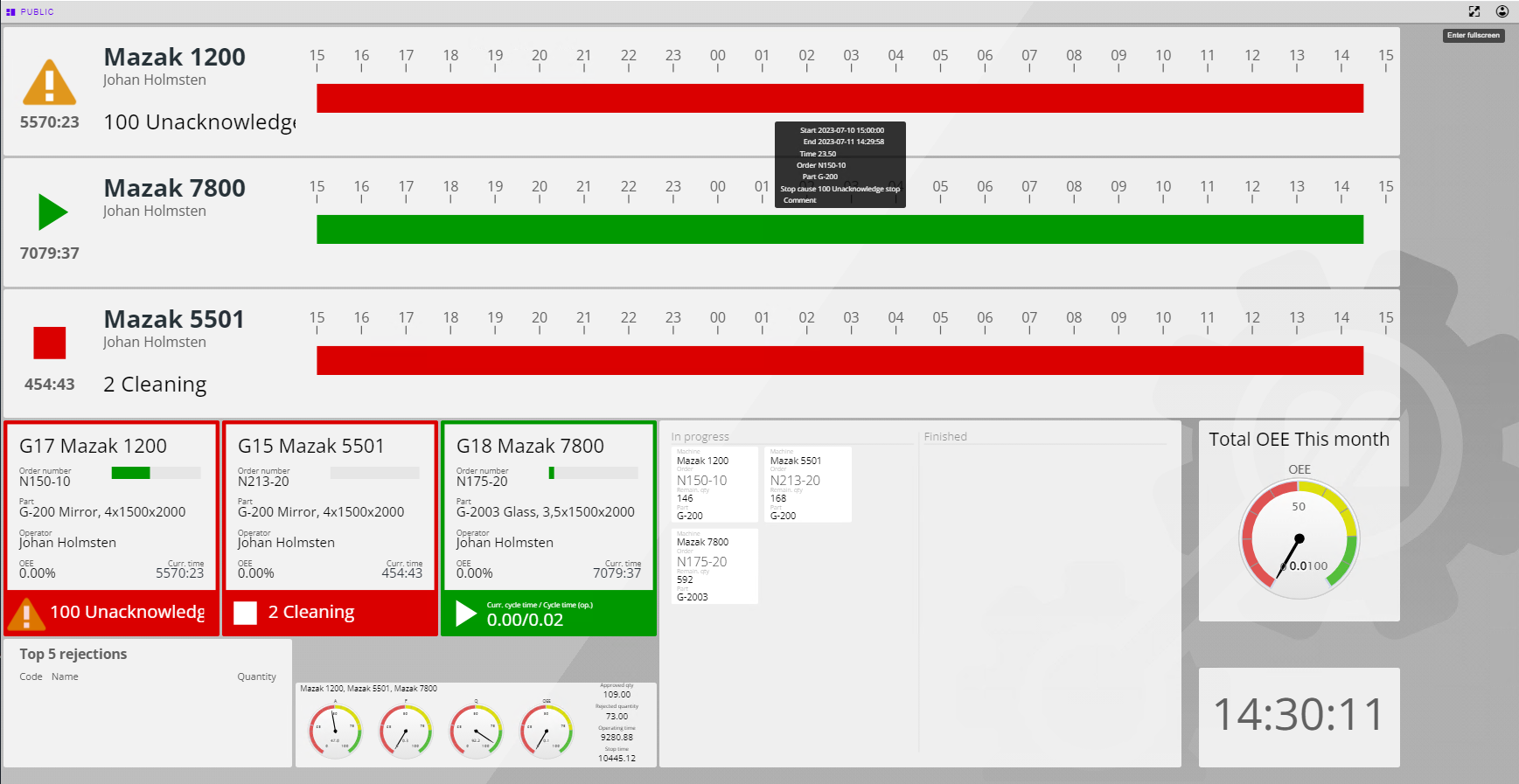

MI also has a web-based dashboard that can be configured however you would like. The dashboard can be used to get a quick overview of your machinery. You are able to see your machine's current status, current OEE value, which orders are in production and what the status of them etc. You can then display this dashboard on different screens around your factory.

MI Reports is a web-based reporting tool that allows you to easily create reports from data such as stops, operation times, rejections, manufactured quantity, OEE, on duty times, cycle times, etc., which can be used for follow-ups and decision-making.

With a high level of automation, it is important to follow-up on stop times and machine usage.

MI helps you with the following:

- Stops are reported by the machine – The operator selects a stop cause and it is possible to follow up the on duty time of the machine.

- Quantity is continuously reported by the machine – Manual quantity counts and reporting is no longer required.

- Follow-up of pace and planned finish time – You can get an overview of your machinery's status and use a tempo board. You get a clear, visual machine monitoring.

What result can you get?

There are many benefits of MI:

- More accurate reporting

- Reliable post-calculations (profitable/non-profitable products)

- Less and more straight-forward manual reporting for operators

- Improved machine monitoring

- OEE reporting

- Better control over total profitability

The technology behind it

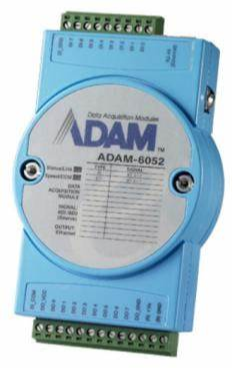

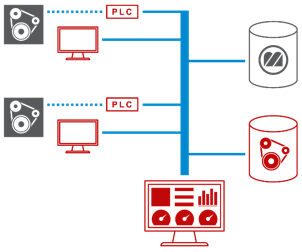

Each machine has a PLC (see image) or OPC connected to it that interprets the signal from the machine and reports it to Monitor ERPMonitor ERP. It transmits a signal when the machine is in operation, and a signal when a piece is finished.

As well as the PLC or OPC, you also need an MI server and a machine terminal per machine (marked in red in the image to the left). You can then connect as many dashboards as you wish (the red screen with a diagram).

When is PLC or OPC the best choice?

Whether you should use PLC or OPC to gather data depends on a number of factors. OPC enables you to collect data for more than operation status, details produced, rejections, etc. With OPC you are able to also gather external measurements such as temperature, power consumption, grip strength, etc. These measurements can then be used to create BI solutions such as being able to find out what the temperature was at a certain point of an order. You are also able to see the exact grip strength of a certain detail produced. This does however put more demand on you as a customer using an OPC as you need to set up and implement an OPC solution that MI can connect to. A PLC is easier to manage with an electrician.

How can I get up and running?

Contact our sales department if you are interested in MI and they will help you get started. A pre-study by one of our consultants may be necessary to see whether MI suits your business.

This option has its own online help. Click here to be redirected to it.